Capitol dome gilded in gold leaf

/Highly skilled artisans with the Gilders’ Studio have restored the lustrous gold leaf finish on the Capitol dome, which is the culmination of significant restoration work on the dome.

The Capitol dome is constructed of copper gilded in gold leaf. The entire structure needed to be repaired to address punctures, tears, dents, failed seams, corrosion, paint coating failure, significant water leakage, and many missing and loose elements. The damage is mainly from hail and 130 years of life and weather deterioration.

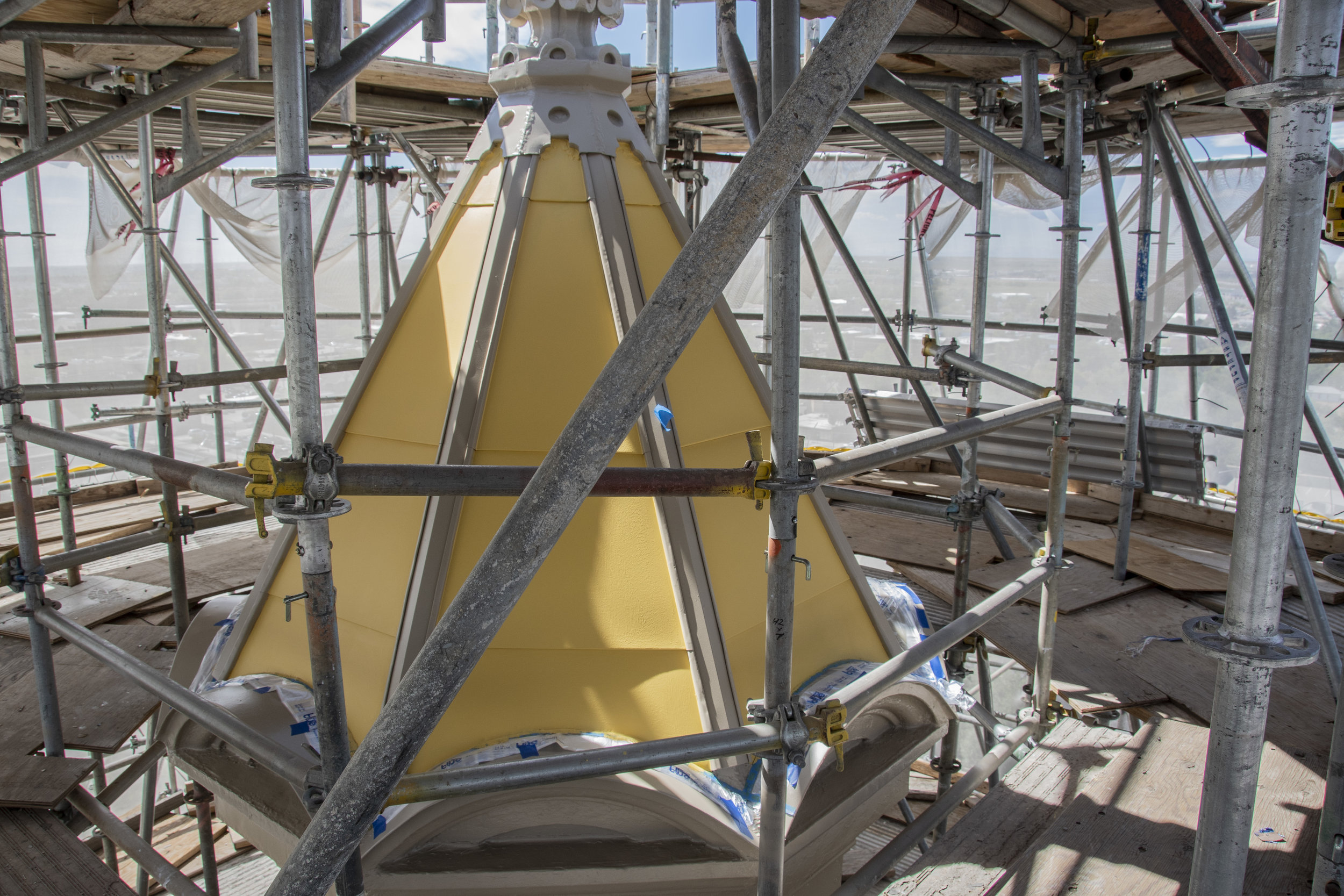

Before gilding, craftsmen with Renaissance Roofing, Inc. finished the decorative pieces on the upper sections of the Capitol dome. Due to the extensive damage, the original pieces were removed and recreated from copper and later painted to match the rest of the entablature on the Capitol.

The glimmering dome panels are covered with gold leaf. The extremely thin sheets of gold are imported from Italy. The gilding process used one Imperial ounce, that's 28 grams, of gold per 100 square feet, totaling about 7 ounces of gold.

The entire gilding process took six days, including the time to prepare the surface of the copper panels. The first step was to wash the panels with alcohol to remove grease or anything else on the copper. Then, the gilders masked off the painted decorative metal for protection.

After masking the area, an etching primer, composed of a phosphoric acid solution, is painted on the smooth surface of copper. The solution creates a dull surface and neutralizes any patina on the copper.

Painting on a phosphoric acid solution

To ensure full coverage, the first step is to outline the panels and then fill in the panel with the etching primer.

All the panels but one have been covered with the etching primer, which dulls the surface of the copper.

Once the etching primer dried, the gilders applied a zinc chromate primer. The primer is canary yellow, which helps emphasize the coloring of the gold leaf. The first coat of zinc chromate dried overnight, and then the gilders put another coat on the next day.

After the second coat of zinc chromate dried overnight, the gilders painted on a slow-drying varnish, called the size, made in Italy. When applied, the clear coat glistens.

After drying overnight, the oil size is just barely tacky, which is called a whistling tack. The size acts almost like glue, allowing the gold to stick to it. The wheels used to roll the gold leaf onto the size are handmade to specifications of the Gilders’ Studio. The gold leaf adhered to the dome with the lightest roll of the wheel. The gold leaf was also custom made for the project, to the specifications of the Gilders' Studio, by Giusto Manetti Battiloro of Florence, Itlay.

The gilders first outlined all panels with thin strips of gold, allowing them to follow the lines with their wheels. This process wastes less gold.

After the panels are covered in gold leaf, the gilders fill in any holes, called holidays, with the gold that is remaining on the paper. The gilders gently press the paper on the holes, transferring the gold leaf to the size. Any hole in the gold will allow the ultraviolet rays of the sun to get through and start to break down the size and primer layers.

Once the panels are covered with gold, the gilders start skewing, which is the process of pressing the gold leaf down against the varnish to remove the excess gold flakes.

The gold leaf doesn’t stick to itself readily, just to the stickiness of the varnish, leaving excess gold flakes on the panels. The skewing process will press down these flakes.

The gilders smooth out the gold leaf using a small brush composed of exceptionally soft Russian squirrel hair.

The gilder brushes the final strokes horizontally creating a more brilliant sheen. When the sun comes down from above, the rays bounce across the horizontal brush strokes in the gold.

No other exterior finish has the enduring luster of gold. With the repairs, the gold leaf dome will continue to stand as a beacon shining over Cheyenne for many years.

The gold leaf dome of the Capitol is an icon in Wyoming. In fact, there are only ten states, including Wyoming, that have gold leaf domes.

When the Capitol was completed in 1888, the copper dome was not gilded with gold leaf. Photo courtesy of Wyoming State Archives.

Tuttle & Hawes gilded the dome with 22-carat gold leaf for the first time in 1900. The dome has been gilded five other times before this restoration project. In this photo, circa 1915-1916, painters from the Sherman Company stand around the base of the dome. Photo courtesy of the Wyoming State Archives.